Why Retreading?

Tyre manufacturers these days, design tyres to offer service, greater than the tread will last. By retreading the tyre casing, an operator can harvest the benefits of these greatly designed tyres. One of the key benefits is lowering the money spent on tyres. It costs about 25% to 30% of a new tyre to retread a tyre casing. Two retreaded casings are worth one new tyre.

Retreaded tyres are enduring as long as a new tyre, and in some cases even longer. With the savings from retreading a tyre, an operator can significantly reduce their cost-per-kilometre and still achieve or exceed the same number of kilometres driven per tyre.

Retreading tyre is one of the most effectual ways to reduce and reuse tyres. Not only will this save money, but it is also the eco-friendly way to help the environment because we can use the tyre casing multiple times after the original tread is worn off.

Oil is an important component in the manufacture of tyres. A retread uses about 1/3 of the crude oil needed to manufacture a new tyre. Retreading is a crucial part to conserve our natural resources as well as utilizing the tyre casings instead of dumping them into landfills or reducing them to ashes.

Retreaded tyres are an unfussy way a company can help to be.

Tyre retreading can be done on tyres of

Airlines

Buses

Cars & Motorcycles

Rikshaws

MPV & Jeeps

Trucks

Tractors

OTR (Off the road)

Our Products

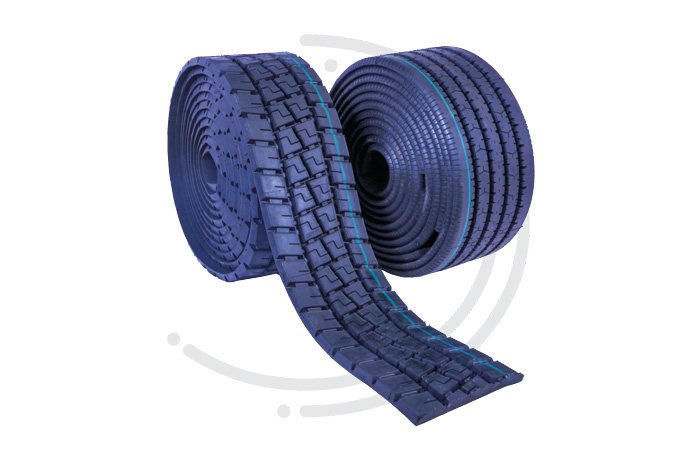

- Conventional Tread Rubber

- Pre-cured Tread Rubber

- Black Vulcanizing Cement

- Cushion Gum [BG]

- Under Tread Strip [UTS]

- Chemical Vulcanizing Fluid [CVF]

- Tube Repair Materials

- Tyre Repair Materials

- Biased Tyre Repair Patches

- Radial Tyre Repair Patches

- Universal Patches

- Plug Patches